Garden Studio Designs

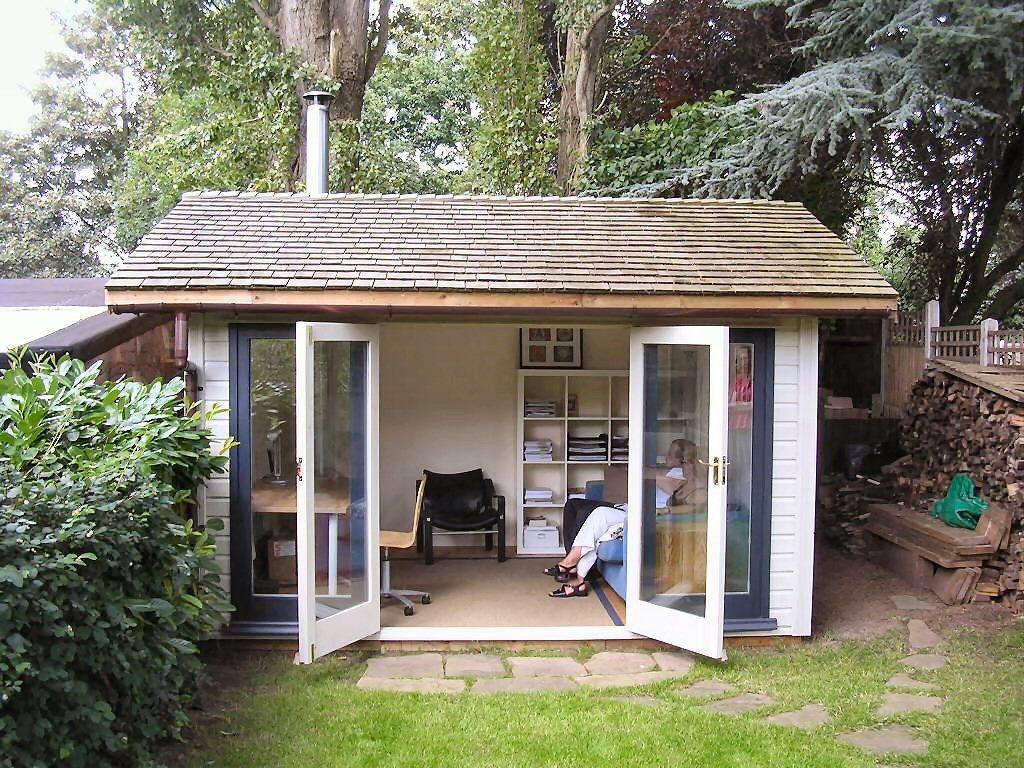

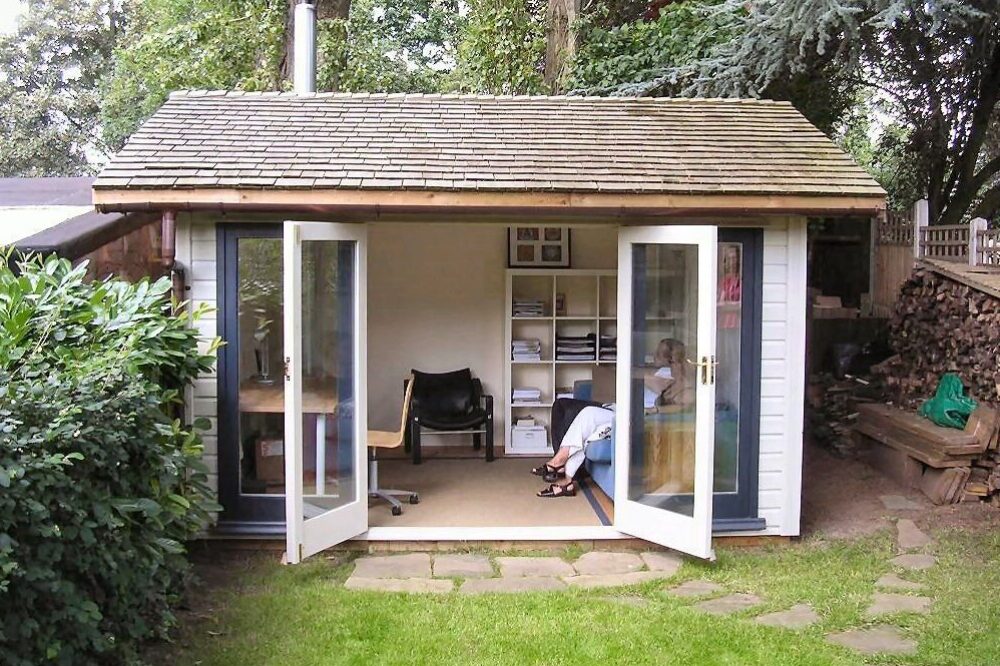

The Studio is a traditional style building with a pitched roof, benefitting from French doors and windows. Available at ridge heights of 2.5m high and the more luxurious 3m high, the vaulted ceilings certainly give the feeling of space.

For those that can be 2m from the boundary, the larger, more spacious option is a must for Artists, as the extra height allows for easels to stand up to their full height.

The studio looks smart in shiplap, stunning in cedar and fabulous in feather edge, especially with the upgrade to Tapco Slate roof tiles.

Taller height buildings can also benefit from the open roof truss, adding a feature that the modern designs can’t match. This attractive feature can be seen on our showroom model, and really adds the wow factor to the interior look of the building

Garden Studios

Starting from £11,500

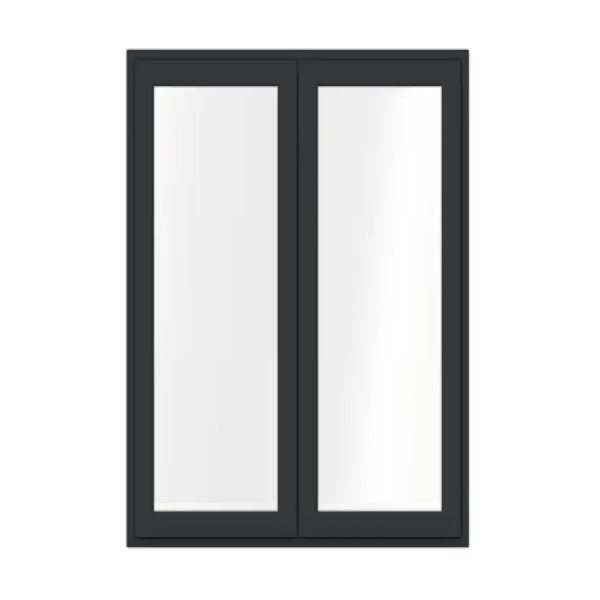

- UPVC French Double Doors

- Two UPVC Side Screen Windows

- One UPVC Casement Window

- Choice of Cladding

- Choice of Roof Material

- Fully Insulated with either Rockwool or PIR insulation

- Internal Spotlights, Consumer Unit, 3 Double Sockets & Switch

- Choice of Laminate Floor

- Garden Studio assembled by our fully trained staff

Build your Garden Studio Office

Please use the button below to start designing your Garden Studio. In the configurator, you will be able to choose the style and position of doors & windows, along with all the optional extras you require.

If the size you have in mind for your Garden Studio is not listed, please use the closest size up.

Once you have designed your Garden Studio Office this will give you a total cost that is inclusive of VAT, Delivery & Installation.

Build yourGarden Studio

The Myriad Uses of a Garden Studio

Your garden studio building will be a dedicated and private space for your craft, whether you’re looking for a room to develop photographs, write, paint, record music or more. It can be a great place to create professional work full-time, or to grow a hobby into a career. Here are just some of the potential uses for your garden studio:

A Garden Music Studio

Thanks to technical advances and the multitude of avenues to publish and promote your own music, many of the breakthrough musicians in recent years have recorded, mastered, and released albums themselves. Your ideal garden music studio can be small enough to make electronic music at a workstation, or large enough to record a live band, fitted out with everything you need to make songs from your garden. You can easily install soundproofing to ensure that your recordings are high quality and that your neighbours aren’t disturbed. Having a full music studio in your garden will allow you to record whenever inspiration hits, without having to worry about the limitations that come with paying for studio time.

A Garden Writing Studio

Virginia Woolf wrote of the importance of “A Room of One’s Own” when looking to become a writer. Having a private space to focus, organise notes, and transport yourself is essential for many writers. Whether you are a published novelist or an aspiring writer, having a garden writing studio will create an easily accessible space for you, letting you bask in the natural beauty of your garden. This can be a great choice for those who lack the space within their own house but don’t want to move or rent a separate room elsewhere, fully insulated and double glazed for year-round use.

Garden Art Studios

Having a quiet space where you can focus is ideal for the creation of art, be that painting, sculpture, photography, or textile manufacture. A garden art studio can be that space for you, giving you a year-round sanctum that is separate from your home while remaining quick to access. This makes it easy to fit art around a busy schedule, or to work from home producing professional art in your own garden. Different sizes of garden rooms can benefit those working on larger projects like sculpture, while smaller garden buildings can be ideal spaces for fine work or digital art.

Internal Views

Make it Personal

Internal Lining

All of our garden studio buildings come with the choice of either unpainted* T&G lining boards or unpainted* 12mm plywood boards with joining strips.

*Please note, these garden studio buildings have been painted by the customer after installation.

If you would prefer to plaster your office after installation we would recommend choosing the non-insulated, non-lined and no electric option on the configurator. Alternatively you can add your own plasterboard on top of the lining provided with your Garden Studio.

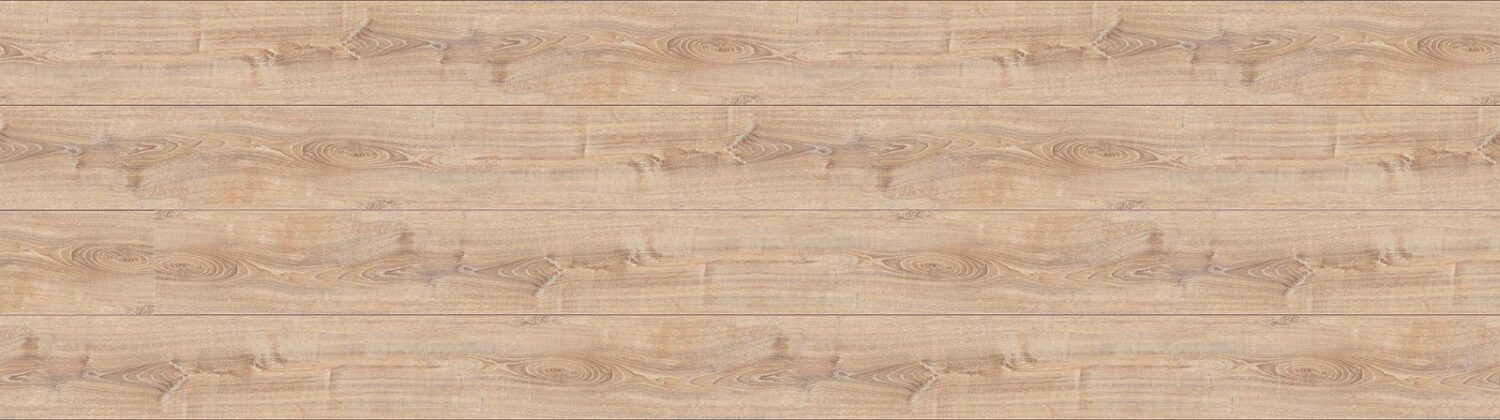

Flooring

All Garden Studios come with a 15mm plywood floor which sits on floor joists. The floor is insulated with 70mm PIR insulation and has a DPM built-in. We offer 4 different colour options of the laminate floor as an optional extra, or alternatively, you can choose to supply and fit your own flooring on top of the 15mm plywood.

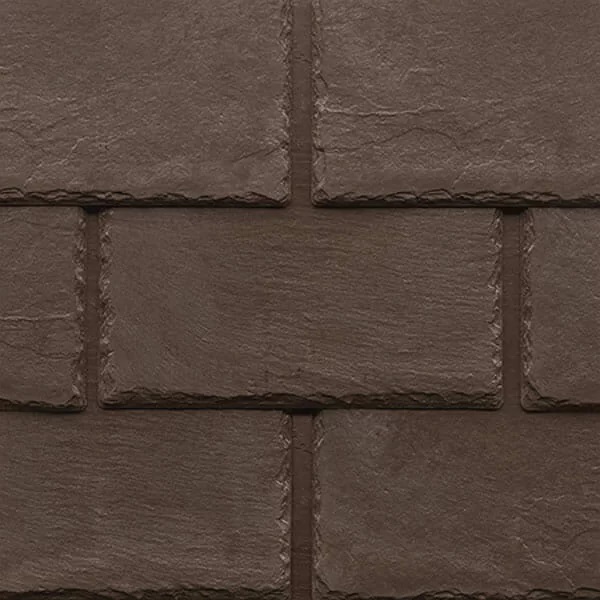

Roofing Options

The Garden Studio Range includes felt tiles as standard. These are available in Dual Brown or Slate Grey and are finished in a square butt design.

Tapco Slates are available as an optional extra – Pewter Grey is the standard colour, but we can provide other colours if preferred.

Please ask for more details on the colour choices for Tapco Slate

All roof materials sit on underfelt and boarding – with the Tapco Slate having the additional benefit of timber battens between the boards and the tiles.

2.5m High Studio Ceilings

Ceilings for the 2.5m high versions include spotlights in a panel that spans the width of the gable end. The panel is fixed to the underside of the ridge beam and to the roof slope on both sides. Internal headroom for this model is 2.15m from the floor level.

LED panels can be surface mounted to the internal board if you prefer to have this type of lighting instead of spotlights. Unfortunately this model is unable to have LED panels in the angle of the roof as the boarding will still be fitted to the underside of the beam.

Should you wish to remove the panel and fit your own lights, please contact us for details on how you can finish after assembly.

Ceilings on Taller Height Buildings

Standard ceilings on the taller height model are the same as the low height model. There is however, scope to remove the ceiling board and either have no lights or LED panel lights.

If choosing the LED panel, they can be located in the roof panels that slope from wall to ridge (see our current show model for details).

Alternatively, we can leave a single (or couple of) cable(s) so that you can supply & fit your own pendant lights. This has the benefit of the ridge beam looking as per the picture.

Roof Trusses

Buildings over 5 wide from gable end to gable end will require a truss to support the roof. This is the case for all buildings regardless of ridge height.

The low height buildings have the trusses clad on both sides with plywood, as do the taller height buildings by default.

On the taller height buildings, should you wish to have an open roof truss please let us know, as this can be provided instead of the lined trusses.

Such is the beauty of the open truss, it could be that you wish to add it as a feature on smaller buildings. Please ask us for details if this is the case, as the amount and position will impact on the additional costs involved.

Windows & Doors

The Garden Studio range comes with fully glazed UPVC doors and windows UPVC doors and windows are available in 7 different colour options with 4 choices of colours for the handles and hinges.

Doors are fitted with a multi-point lock that is insurance recognised. Windows are fitted with standard residential locks.

The windows and doors for the Garden Studio come as standard with 28mm thick double glazing but can be upgraded to triple glazing at an additional cost.

-

Black

-

Anthracite Grey

-

Agate Grey

-

Chartwell Green

-

Irish Oak

-

Cream

Options

Roofing Options

The garden studio is available in two height versions. To comply with planning restrictions the 2.5m high version can be placed next to a boundary.

Taller height garden studios can be sited 2m away from the boundary, or close to the boundary subject to planning permission.

Both versions have the following roofing options

-

Brown Felt Tiles

-

Grey Felt Tiles

-

METAL BOX PROFILE

-

TAPCO SLATE

-

ONDULINE SHEETS

-

Cedar Shingles

Options

Groundwork Requirements

For the last 30 years, we have tested the various options that are available for the garden building groundwork – remember… this is not a garden shed. Available solutions are a concrete or paving slab base, ground-screws with a timber frame, suspended floors on piles, or timber decks above ground level.

The conclusion is… the best solution for the building is a ground supporting base.

A ground supported base is either a concrete pad or a paving slab base, and requires the soil to be dug out, and shuttered around the perimeter. The shuttering has a damp proof membrane, half filled with compacted hardcore, and finished with either concrete or smooth slabs. Your slab needs to be flat and level, constructed to the same size as the building, and can either be done by your local builder or by one recommended by us.

The easiest solution is often a ground screw base, as this requires less man power, machinery and raw materials. It is also something that we can provide as a option for majority of cases. This would only be suitable on sites that are clear of debris, solid surfaces, and level within 200mm.

Dimensions

| External Height (To Ridge Point) | 2.5m or 3.0m |

|---|---|

| Internal Height (To Ridge Point) | 2.1m or 2.6m |

| External Depths | 2.4m - 4.2m |

| Internal Depths | 2.2m - 4.0m |

| External Widths | 3.2m - 6.2m |

| Internal Widths | 3.0m - 6.0m |

Delivery & Installation

You can find out your delivery costs by entering your postcode on the configurator. If the website cannot provide you with a delivery cost for your Garden Studio, please still submit your configuration and we will be in touch.

Installation is included within the overall cost of your garden studio buildings. However, we can offer a supply only discount should you choose to erect the building yourself.

FAQ's

Do you have any recommendations for the additional electrical work?

Andy Punnett – A.S.P Electrics – 01926 428228 / 07880 717018 (Warwickshire)

info@aspelectrics.co.uk

George Whyman Electrical (also on CheckaTrade) – Stratford on Avon – range 25 miles

07938 952253 – www.whymanelectrical.co.uk

Andy Wood – Hertz Electrical Contactors – 01788 541403 / 07875 146350 (Midlands)

Blaby Electrical Systems – Leicester – 01162 883493 (Leicester / Nottingham / Warwickshire / Northants)

Luke Robbins Electrical – within 1 hour of Warwick – 07886 182379

lukerobbinselectrical@gmail.com

Robert Williams – Riviera Electrical – 01327 317210 – Daventry / Banbury

sales@rivieraelectrical.co.uk

DCM Electrical – Matt – Kenilworth – 07931 353717

Berkhamsted Buckinghamshire – Andrew Berkleigh – 07919 160663 – andrewberkleigh@sky.com

Do you have any recommendations for groundwork contractors?

Daron Langford – Warwickshire – 07739 695442

Dave Bashford (Elite Builders) – Solihull/West Midlands – 07899 893815

Paul Oliver – West Midlands – 07778 215889

Chris Woolmore – Rugby – 07828 437903

Tim Pearman – Worcestershire – 07831 477585

Woolliscroft Groundwork – Worcestershire – 07961 668971 – https://woolliscroftgroundworks.co.uk/

Kelvin Hughes – Evesham – 07973 361143

Ben Harwin – Cambridgeshire – 07960 033476

Scott Mccue – Leicestershire – 07916 138164

Urban Diggers – Hemel Hempstead – 07846 430271

Shadow Environmental Services (Removal of existing buildings/asbestos) – London, Nottinghamshire, Derbyshire and Leicestershire – 0207 226 6990 / 07918 070210

What groundwork is required for a garage?

Concrete Pad & Single Brick Course – Scroll down for full details:

150mm compact hardcore: DPM: 150mm concrete: Single course of semi-engineering bricks

Please allow 50mm additional concrete in addition to the size of your garage.

Your groundwork plan is issued when your order is placed and your final design is confirmed.

We allow a 5mm tolerance for the brick course – please use a laser level when setting the bricks.

In most cases the base is too large to dig by hand, hence a local contractor will be required to do the groundwork for you.

You start by digging out the ground down to a depth of 12 inches, with any spoil either removed by skip off site, or dispersed somewhere else on site.

Secondly the land / mains drains will be put in place, and soak aways will be constructed. The soak away will be a deep pit, about 1m x 1m x 2m deep and filled with gravel, with the drainage piped into the top of it. This is mainly to take the rainwater from the guttering.

Once the drains are prepared, the hardcore is put in to a depth of 150mm and compacted down. Once compacted, the shuttering around the edge is put in place.

The concrete is to a depth of 150mm, and should be a c40 mix, or a mix with fibres. For example a 6m x 6m square base will need 6m x 6m x 0.15m = 5.4 square metres of concrete. A tamped finish is sufficient, although a floated finish will be smoother. Timescale for this should be a single day.

Once the concrete has been laid for a couple of days the brick course can be fitted. This should take about half a day for the 6m x 6m base.

For more details click here

What groundwork is required for garden offices?

Concrete Pad or Paving Slab Base

150mm compact hardcore: DPM: 100mm concrete: or

150mm compact hardcore: 50mm paving slabs on cement sub base

Garden rooms and offices require a flat & level pad of either concrete or paving slabs.

The base will need to be at least the same size as the building you are looking to have, and you

will require 400mm clearance to objects such as fences, trees or other buildings.

We can work within a 10mm tolerance (which a competent builder can easily achieve).

Alternatively, if you are within our standard radius we are able to offer the option of a ground-screw base (on certain models).

What access do I need in to my garden for you to install the building?

We require a minimum of side access of a minimum width of 600mm and a height of 1950mm to allow us to install your building. Should you be concerned about access in to your garden please email us pictures of the access and we will be able to confirm whether it is suitable.

What size vehicle are the buildings delivered on?

For the majority of our buildings, they are delivered on a 7.5 tonne lorry. This is the typical size of a concrete mixer lorry and will take up the equivalent space of 2 standard vehicles. We will require parking for our vehicle as close as possible to your property.

Is my garden room/office suitable for year round use?

The Garden Rooms and Offices are fully insulated for year round use. They are designed to be warm in the winter and cool in the summer, however the location in your garden will have an impact on how warm / cool the building is.

North faced gardens will have buildings that are naturally cooler throughout the year, whilst south facing garden will be naturally warmer throughout the year.

A building in the shade or in a north faced garden, will need a small heater during the winter months, but will remain cosy when the building is up to temperature.

A building in direct sunlight or in a south facing garden will benefit from more ventilation and blinds between the glass to keep the building cooler.

The size I required isn’t listed, can you still build it?

The price list has been created to give a price for our most common sizes. If you require a different size to fit in a space available, please contact us to get an accurate price.

Because each building is individually created for you, a guide for the price would be the closest to the size that you are looking to have. Please do get in touch on 01926 815757 and talk to us about your project.

How long will my building take to build on site?

Garden Rooms are usually constructed within 1-2 days (up to 6.2m x 3.6m sizes) depending on the final specifications.

Garages up to 6.1m x 6.1m are usually constructed within 1 day. Larger buildings will often take 2 days on site.

Commercial Buildings usually take 1 week on site – depending on the final specification.

How long will my building last?

We regularly have customers that have buildings re-roofed at 15 and twenty years old – who are quite confident that their buildings will last double that time if they get general maintenance and care.

This building was taken by a customer and we have worked out that it was 18 years old, and was still original. The customer has painted the building regularly with Protek Woodstain.

This garden office is 12 years old and has been regularly treated with Dark Oak wood protector. It features timber doors and windows, along with brown felt tiles.

This garage is 24 years old and still has it’s original layer of green mineral felt.

This garage is over 30 years old, and was bought by one of our first customers. Finally the customer passed away and the house has laid derelict for 2 years, hence the unkept look.

What is the lead time?

The lead time for a building can vary between 2 – 6 months.

You are welcome to book in advance to secure a delivery slot, and still make adjustments to the design up to the point that the base has been constructed.

(Please note that items that have been specifically order for you will still need to be paid for)

Is tanalised timber waterproof?

Tanalised timber is not waterproof, so it is still subject to the natural expansion and contraction as the moisture content in the surrounding atmosphere changes. It advised that a water repellent (clear or colour) treatment is applied to not only maintain the appearance of the building but also to help to exclude moisture being absorbed by the timber surfaces.

Can my garden room be used as a music studio?

We can provide RWA45 Rockwool acoustic insulation in place of the standard insulation and the option to upgrade to triple-glazed doors and windows.

RB Studios in Birmingham have utilised 5 of our garden offices as music studios. These studios have been used by many famous Artists and Bands, and are Birmingham’s longest established recording and rehearsal studios.

How do I get internet to my garden room/garden office?

There are two ways to get internet to the new Garden Office.

Option 1 is to have a CAT 5 cable coming from a router in your house, down the garden and into the back of the building.

We can supply a back box specifically for a CAT 5 cable. Usually the cable is better to be unbroken – hence we don’t internally wire with a CAT 5 cable to pug into

Option 2 is to purchase a WiFi extender kit or a mobile data dongle.

Please explain the electrics?

Garden Rooms and Offices include the first fix wiring, along with the consumer unit, lighting and the faceplates.

All wiring is installed within the cavity and is ready for an electrician to connect the tail ends of the wiring at the consumer unit and the faceplates.

The electrician will need to provide and install a power feed from your house / garage to the new building – usually a 6mm armoured cable is used. The wiring provided is 1.5mm cables for lighting on a 6 Amp fused circuit, and 2.5mm cables with a 32 Amp breaker for the sockets – on a ring main.

There is space for a 3rd breaker if it is required for another feed.

It usually takes half a day for the internal connections, plus the time required for the electrician to install the cable that you require.

Our electrician can offer customers in Warwickshire and Worcestershire with installation and certification independently – please contact him directly (Andy Punnett) via his website www.aspelectrics.co.uk If you live in Berkshire or Hampshire, please contact Ben Thorp on 07917 131984

Please explain the window options available?

We have suppliers for u-PVC and aluminium windows, all of which can be fitted into any of our buildings.

u-PVC Windows are the standard option for Garden Rooms and Offices due to their maintenance free properties. Available in a a choice of colours, but usually supplied in the popular Anthracite Grey or Black. The u-PVC windows can be fitted into any of our buildings and it is becoming increasingly more common to have them in garages and workrooms.

Aluminium is usually provided as bi-fold doors. Windows are available in Aluminium again available in a range of colours – with Anthracite grey being the most popular choice. You can select u-PVC as this also matches the Aluminium Bi-Fold doors.

Please explain the cladding options available?

Shiplap – 16mm x 125mm Scandinavian Redwood machined to our unique profile, with an extra long rebate to allow for natural movement of timber. It is pressure treated to a light green colour to protect against rot & decay for 15 years and is the ideal choice for customers who like a smooth finish and little maintenance.

Feather Edge – 25mm x 150mm home grown spruce with a sawn finish, that provides a much thicker and heavier look to the shiplap. Again it is pressure treated in a light green colour, and is the ideal cladding for customers looking for a traditional looking building that is full of character. The size and weight of the feather edge along with the manufacturing processes mean that this board is a more expensive option over the shiplap cladding.

Cedar – 12mm x 100mm Tongue & Groove cladding machined to create a modern looking finish. Each board is unique as this beautiful cladding naturally ranges from a dark hardwood to a light pine in colour thus creating a fantastic looking natural building. The hardwood properties of Cedar mean that it hardly expands or contracts during changes in weather, whilst it also has it’s own unique protection against rot, decay and insect infestation. Whilst the Cedar will fade in the sunlight, it is a must for customers looking for that wow factor on a garden room or garage, and it will continue to offer that feeling especially if protected against UV rays with Restol Oil.

Please explain the roofing options available?

Pitched roof buildings can have any of the roofing options that we provide, whereas the single slope buildings are only available with steel roofing sheets.

Felt Tiles is standard on the pitched roof garden rooms and garages. They are created in a sheet format that has 4 tiles on each sheet – the above tile covers the lower sheet by 50% to provide a double layer of tiles. In addition to this we also cover the roof with breathable underfelt before the tiles are fitted – which creates a 3 layer roofing system with an average lifespan of 15 years.

Steel Roofing Sheets are covered with plastisol and available in a range of colours. It is fitted to the roof onto the breathable underfelt to create a 2 layer roof covering that is condensation free. When fitted to the Garden Offices the insulation in the roof ensures virtually no noise is heard during inclement weather. Average lifespan is 25 years for the steel sheeting.

Onduline Roofing is a standard roof finish for stables. It is felt and bitumen compressed into a corrugated format and can be nailed directly onto the purlins with or without boarding underneath. For the optimum life expectance of 15 years we would recommend boarding and underfelt as a base for the Onduline to sit onto. The Onduline can sit directly onto the purlins however this will reduce the average lifespan of the product. (Only available on equestrian buildings).

Tapco Slate is a perfect solution for customers looking for a tiled roof look, but would like the building supplied & fitted by one company. Fitted onto boarding, underfelt & battens the Tapco slate is a man made lightweight roofing solution that appears as realistic as natural slates. Available in a range of colours, with a maximum roof pitch of 25 degrees, the average lifespan is 40 years for this roof finish.

Green mineral felt is a polyester based felt and is much thicker and stronger than normal shed roofing felt that you would buy from a DIY store. Average lifespan is 6-8 years.

Clay or Slate Tiles @ 30 degrees. Customers that require this finish will require a tiler to supply & fit the battens, membrane, tiles and soffits for this option. Warwick Buildings will obtain the trusses and install them at 600mm centres in readiness for the tiler to continue from that point. The two end trusses will be clad, however please note that there will not be any overhangs to the gable end on this option.

How much clearance do I need around my building?

We require a minimum of 600mm around the building to be able to fit the cover strips and guttering on the outside of the building.

If you have less space available please contact us on 01926 815757, as we will discuss the options available on an individual basis – it may be that we can still accommodate your project.

What can I have without planning?

Buildings close to a boundary will need to be 2.5m high. If you require a taller building without planning you will need to be more than 2m away from your boundary.

You will need to locate your building either to the side or to the back of the house – buildings in front of the house will need planning permission.

Please note that the customer is responsible for planning permission, and may need to contact the council for full clarification of their permitted development rights.

If you require planning permission, you will need a local planning consultant or architect to prepare the drawings required for a planning application. We can provide the information for you to allow the drawings to be produced. You can then either submit the application yourself or employ someone to do so on your behalf.

Our recommended contact for this service is Keenan Project Designs Ltd (RIBA)

Mobile: 07507 355 997

Telephone: 0800 233 5787

Email: Luke@kpdltd.com

Website: www.keenanprojectdesigns.com

What maintenance is required?

The weather, location and the sun can all have an effect on buildings, however throughout our 35 years we understand how our product works and how it stands up to the test of time.

Your maintenance schedule should be:

- To clean the gutters out to keep free from debris

- Adjust doors and windows that have expanded or contracted through weather conditions

- Remove debris from the roof

- Treat the outside of the building as required to maintain an attractive appearance. (This provides a waterproof coat to the timber and keeps the moisture content of the wood consistent – which in turn improves the stability of the timber, and reduces the expansion & contraction of the timber)

Our guarantee is in respect of design and manufacturing faults, corrosion and rot for 10 years from the date of installation.