Single Garage

Starting from £8,750

- 1 x Canopy up & over metal door

- Tanalised Shiplap cladding as standard

- Upgrade to feather edge cladding

- Grey or Brown felt tiles or Grey or Black metal box profile roofing as standard

- Roofing option upgrades available

- Personal doors and windows available as an extra

- Partitions available as an optional extra

Build your Single Garage

Please use the button below to start designing your Single Garage. In the configurator you will be able to choose the style and position of doors & windows, along with all the optional extras you require.

If the size you have in mind is not listed, please use the closest size up.

Once you have designed your Single Garage this will give you a total cost that is inclusive of VAT, Delivery & Installation.

Free Online Quote Builder

Groundwork Requirements.

All garage buildings require a concrete base and a single course of bricks, made up as follows.

- 150mm of hardcore

- Damp proof membrane

- 100mm (minimum ) of concrete

- single course of semi-engineering bricks (with holes)

- concrete base size to be 50mm larger than brick course dimensions

- plan to be provided on order

Wooden Garage Groundwork

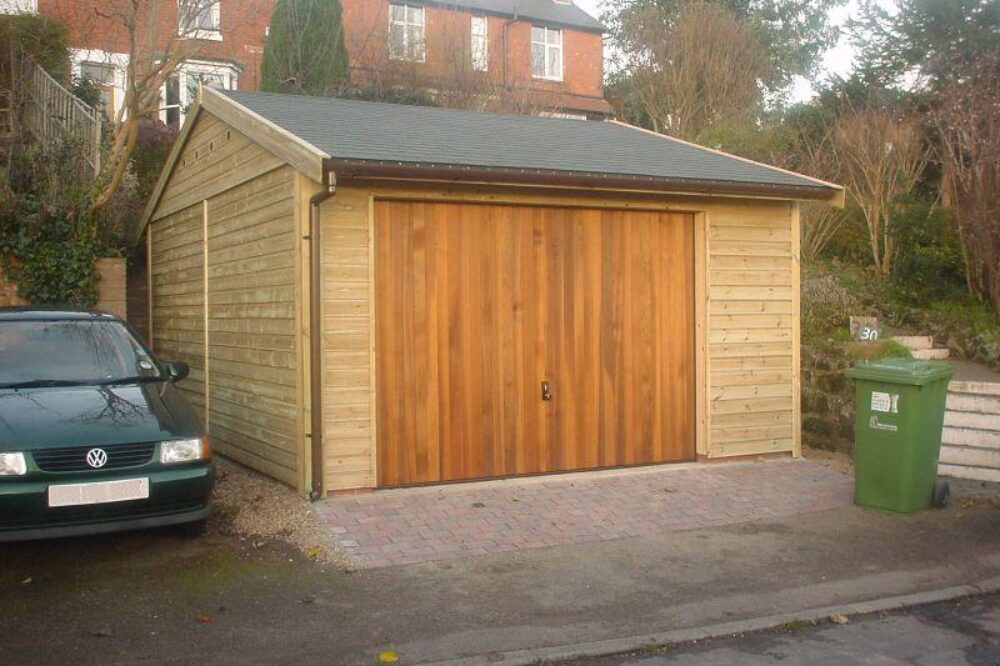

Garage Door Options

Our single garages come with a canopy style metal up & over door, which come in a range of different colours. You can choose to upgrade to fully retractable up & over doors, timber barn doors or cedar clad doors for an additional fee.

The maximum width of our doors is 2.5m and the height is 2.1m. On some designs the doors need to be reduced in height or width. If you would prefer to fit your own doors such as roller shutter doors, then we can leave the openings and you can arrange for a separate company to supply and fit the doors after installation of your garage.

-

Standard Ribbed U&O Door

-

Cedar Up & Over

-

Elegance Up & Over Door

-

Standard Framed Doors

-

Cedar Framed Doors

-

Chartwell Green U&O Door

Options

Roofing Options

FELT TILE ROOF:

This lightweight roofing felt provides a double layer of felt shingles, giving a smart finish to the garage building. In addition is an underfelt that provides the third layer of protection, to provide a long lifespan to the standard finish. Available in Slate Grey or Dual Brown, with colour coded verge and ridge trims.

METAL ROOF:

Steel sheets coated with plastisol, offering a 40+ year lifespan. Available in a wide range of colours, this metal roofing sits onto a layer of underfelt, to protect against any condensation that forms on the underside of the sheet. The OSB boarding also soundproofs the garage, so that it remains quiet inside when it rains.

TAPCO SLATE:

A superb alternative to real slate, especially as the lightweight properties allow us to install quickly and cost effectively. Tapco adds a depth to the roof as opposed to the flat looking felt tiles, and adds a bucket load of character to your new building. Particularly suited to Cart Lodges, and Feather Edge garages.

CEDAR SHINGLES:

Just like Tapco, the Cedar Shingles add that depth of roof that felt tiles can’t match. However unlike any other roof covering, there is no symmetry with cedar shingles, as they are different widths and different colours. Please note tat they silver and curl over time, however this look just be the look that you are hoping to achieve

MINERAL FELT:

Grey mineral felt is also available if you need to trim the budget, or you’re fitting your own roof covering.

ONDULINE:

Black onduline is a compressed felt version of the corrugated tin roof. This option is priced on application and is available for all buildings. Please note that we add the Onduline onto OSB boarding that has been lined with an underfelt. This encourages the Onduline to perform much better than if it were fitted directly to the purlins.

TILED ROOF:

We can supply and fit trusses that are spaced at 600mm centres, in order for clay or slate tiles to be fitted. Priced on application, the customer will need to batten the trusses, tile the roof and fit the soffits.

Internal Views

The framing is visible on the inside of the garages, unless you choose the inside lining option.

On the back of the framing you will see the 4mm plywood, which has the vapour barrier and then the outside cladding.

Inside the building, you will see the purlins (between the trusses) followed by the sterling board (OSB). On the outside of the OSB is the final roof covering.

If you select the option of the internal roof lining (and insulation), the Celotex is fitted in between the purlins, and 9mm plywood is fixed to the underside of the purlins.

Dimensions

| External Height (to ridge point) | 2.5m - 3.3m |

|---|---|

| Internal Height (to ridge point) | 2.2m - 3.0m |

| External Depths | 4.9m - 7.0m |

| Internal Depths | 4.7m - 6.8m |

| External Widths | 3.05m - 4.9m |

| Internal Widths | 2.85m - 4.7m |

Delivery & Installation

You can find out your delivery costs by entering your postcode on the configurator. If the website cannot provide you with a delivery cost please still submit your configuration and we will be in touch.

Installation is included within the overall cost of your building. However, we can offer a supply only discount should you choose to erect the building yourself.

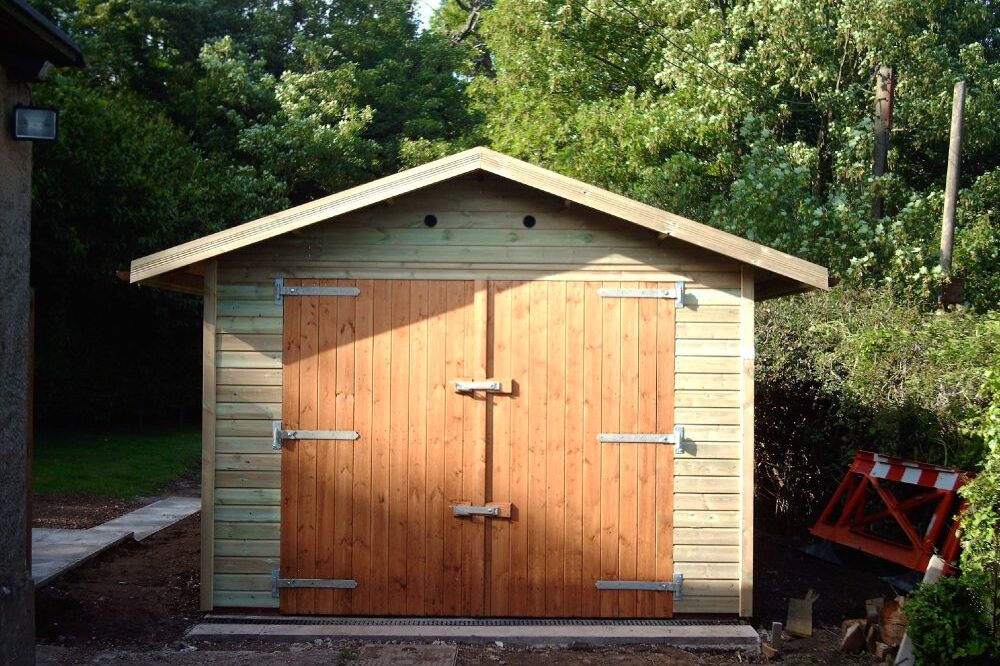

Do I Need Planning Permission?

Permitted development allows most people to construct an outbuilding within permitted development. Providing you meet certain criteria, it is likely that you can have a pitched roof single garage close to the boundary. This is considered to be permitted development, providing the building is 2.5m high (or lower), not in front of the house, and doesn’t cover half the garden.

The image shows an example of this, with a 4.2m wide garage having an eaves height of 2.1m and a ridge height of 2.5m.

If you require a taller height building, then the garage would need to be at least 2m from the boundary, so that it can be erected without planning permission.

Please note that permitted development may be different in your location, as new build houses, AONB and listed buildings may have additional covenants that prevent you from addding buildings without permission.

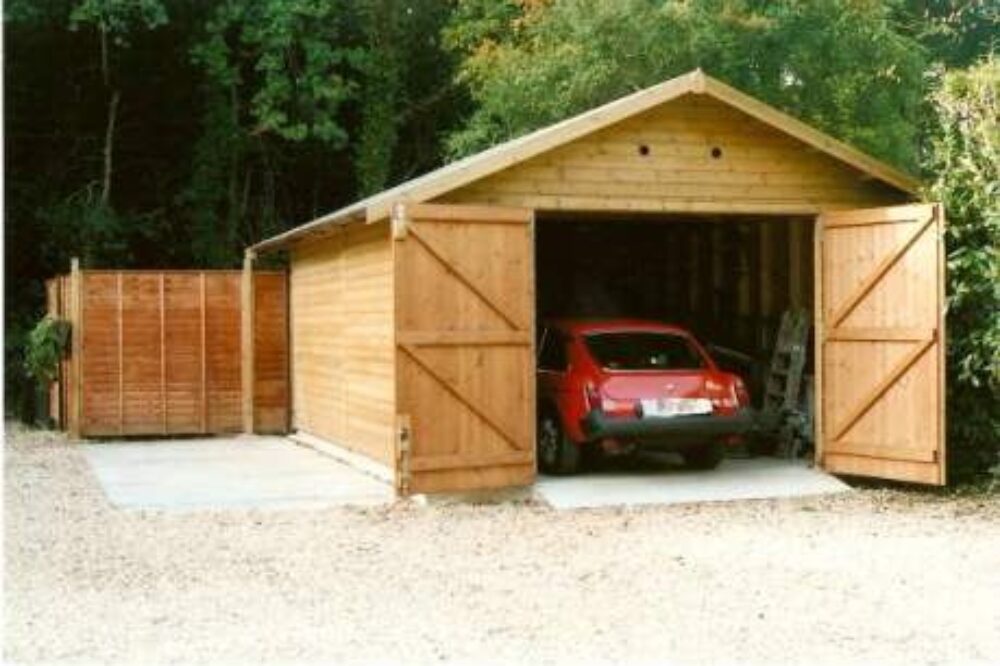

Single Garage & Workshop Combo

Not only is a wooden garage great for storage, but it’s perfect as a workshop too.

That’s exactly why this customer created a combo unit so that he could work on his motorbikes easily.

By extending one half of the garage, this created a single garage at the front and a workshop at the back.

This dual purpose unit also became the perfect man cave, as the customer insulated and lined the workshop area, then added a wooden floor and a workbench on the back wall.

To find out more about how to create a combo unit, please contact us to discuss your requirements.

WOODEN GARAGES - STEP BY STEP BUILD PROCESS

FAQ's

Do you have any recommendations for groundwork contractors?

Daron Langford – Warwickshire – 07739 695442

Dave Bashford (Elite Builders) – Solihull/West Midlands – 07899 893815

Paul Oliver – West Midlands – 07778 215889

Chris Woolmore – Rugby – 07828 437903

Tim Pearman – Worcestershire – 07831 477585

Woolliscroft Groundwork – Worcestershire – 07961 668971 – https://woolliscroftgroundworks.co.uk/

Kelvin Hughes – Evesham – 07973 361143

Ben Harwin – Cambridgeshire – 07960 033476

Scott Mccue – Leicestershire – 07916 138164

Urban Diggers – Hemel Hempstead – 07846 430271

Shadow Environmental Services (Removal of existing buildings/asbestos) – London, Nottinghamshire, Derbyshire and Leicestershire – 0207 226 6990 / 07918 070210

What groundwork is required for a garage?

Concrete Pad & Single Brick Course – Scroll down for full details:

150mm compact hardcore: DPM: 150mm concrete: Single course of semi-engineering bricks

Please allow 50mm additional concrete in addition to the size of your garage.

Your groundwork plan is issued when your order is placed and your final design is confirmed.

We allow a 5mm tolerance for the brick course – please use a laser level when setting the bricks.

In most cases the base is too large to dig by hand, hence a local contractor will be required to do the groundwork for you.

You start by digging out the ground down to a depth of 12 inches, with any spoil either removed by skip off site, or dispersed somewhere else on site.

Secondly the land / mains drains will be put in place, and soak aways will be constructed. The soak away will be a deep pit, about 1m x 1m x 2m deep and filled with gravel, with the drainage piped into the top of it. This is mainly to take the rainwater from the guttering.

Once the drains are prepared, the hardcore is put in to a depth of 150mm and compacted down. Once compacted, the shuttering around the edge is put in place.

The concrete is to a depth of 150mm, and should be a c40 mix, or a mix with fibres. For example a 6m x 6m square base will need 6m x 6m x 0.15m = 5.4 square metres of concrete. A tamped finish is sufficient, although a floated finish will be smoother. Timescale for this should be a single day.

Once the concrete has been laid for a couple of days the brick course can be fitted. This should take about half a day for the 6m x 6m base.

For more details click here

Can I have a garage within permitted development?

In a word, yes

Single garages have a choice of a pitched roof or a single slope roof at 2.5m high – which is within permitted development in most cases.

Double and triple garages will need to have a single slope roof to be 2.5m high.

Double & triple garages with a pitched roof will need to be 2m from the boundary to be within permitted development as they are taller than 2.5m high.

The size I required isn’t listed, can you still build it?

The price list has been created to give a price for our most common sizes. If you require a different size to fit in a space available, please contact us to get an accurate price.

Because each building is individually created for you, a guide for the price would be the closest to the size that you are looking to have. Please do get in touch on 01926 815757 and talk to us about your project.

How long will my building take to build on site?

Garden Rooms are usually constructed within 1-2 days (up to 6.2m x 3.6m sizes) depending on the final specifications.

Garages up to 6.1m x 6.1m are usually constructed within 1 day. Larger buildings will often take 2 days on site.

Commercial Buildings usually take 1 week on site – depending on the final specification.

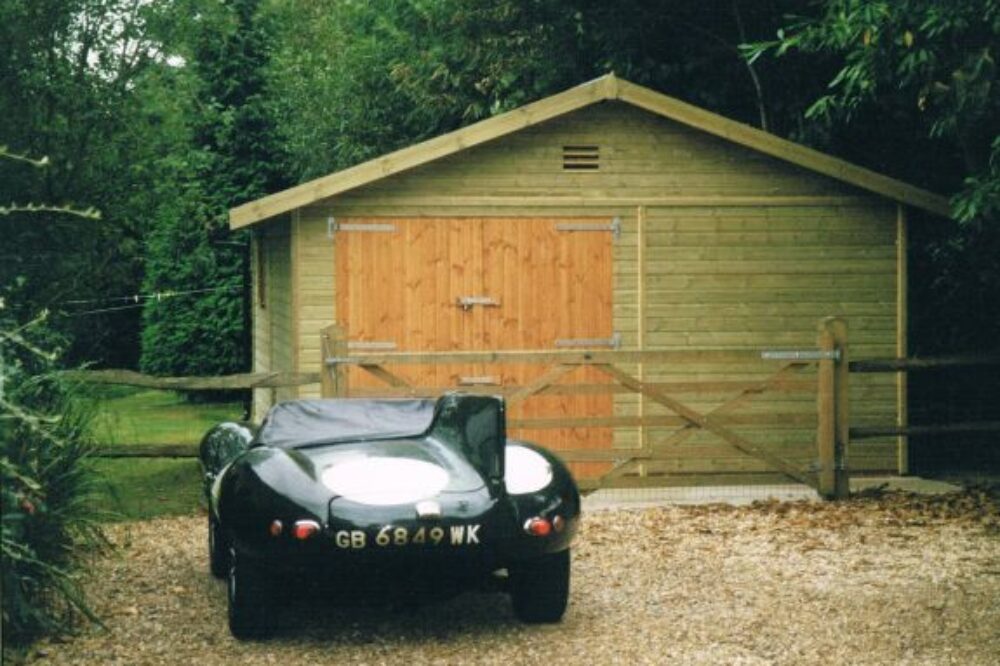

How long will my building last?

We regularly have customers that have buildings re-roofed at 15 and twenty years old – who are quite confident that their buildings will last double that time if they get general maintenance and care.

This building was taken by a customer and we have worked out that it was 18 years old, and was still original. The customer has painted the building regularly with Protek Woodstain.

This garden office is 12 years old and has been regularly treated with Dark Oak wood protector. It features timber doors and windows, along with brown felt tiles.

This garage is 24 years old and still has it’s original layer of green mineral felt.

This garage is over 30 years old, and was bought by one of our first customers. Finally the customer passed away and the house has laid derelict for 2 years, hence the unkept look.

Is tanalised timber waterproof?

Tanalised timber is not waterproof, so it is still subject to the natural expansion and contraction as the moisture content in the surrounding atmosphere changes. It advised that a water repellent (clear or colour) treatment is applied to not only maintain the appearance of the building but also to help to exclude moisture being absorbed by the timber surfaces.

Are all hardwoods more solid than softwoods?

Somewhat confusingly this is not always the case – Balsa wood for example is an extremely ’soft’ wood as is Cedar however both are classed as hardwoods. The high quality softwood used by Warwick Buildings is in fact a ‘hard’ wood and it is this quality which stands out particularly to those who visit the Warwick Buildings Show Site to view the buildings in person – one simply cannot mistake quality construction and materials when seen first hand.

Please explain the garage door options available?

Garage Doors

The garage door default option are Metal Up & Over Canopy Style doors. The standard size of the doors are 2440mm wide x 2135mm high.

Single garages are priced with 1 set, double garages with 2 sets, triple garages with 3 sets and so on.

We offer the following upgrades to the doors that come as standard:

- Framed Barn Style Double Doors

- Cedar Clad Framed doors

- Metal Up & Over Fully Retractable doors

- Cedar Up & Over doors

Please explain the window options available?

We have suppliers for u-PVC and aluminium windows, all of which can be fitted into any of our buildings.

u-PVC Windows are the standard option for Garden Rooms and Offices due to their maintenance free properties. Available in a a choice of colours, but usually supplied in the popular Anthracite Grey or Black. The u-PVC windows can be fitted into any of our buildings and it is becoming increasingly more common to have them in garages and workrooms.

Aluminium is usually provided as bi-fold doors. Windows are available in Aluminium again available in a range of colours – with Anthracite grey being the most popular choice. You can select u-PVC as this also matches the Aluminium Bi-Fold doors.

Please explain the cladding options available?

Shiplap – 16mm x 125mm Scandinavian Redwood machined to our unique profile, with an extra long rebate to allow for natural movement of timber. It is pressure treated to a light green colour to protect against rot & decay for 15 years and is the ideal choice for customers who like a smooth finish and little maintenance.

Feather Edge – 25mm x 150mm home grown spruce with a sawn finish, that provides a much thicker and heavier look to the shiplap. Again it is pressure treated in a light green colour, and is the ideal cladding for customers looking for a traditional looking building that is full of character. The size and weight of the feather edge along with the manufacturing processes mean that this board is a more expensive option over the shiplap cladding.

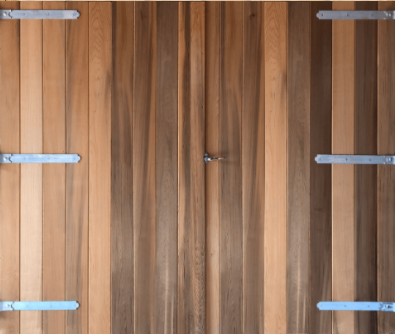

Cedar – 12mm x 100mm Tongue & Groove cladding machined to create a modern looking finish. Each board is unique as this beautiful cladding naturally ranges from a dark hardwood to a light pine in colour thus creating a fantastic looking natural building. The hardwood properties of Cedar mean that it hardly expands or contracts during changes in weather, whilst it also has it’s own unique protection against rot, decay and insect infestation. Whilst the Cedar will fade in the sunlight, it is a must for customers looking for that wow factor on a garden room or garage, and it will continue to offer that feeling especially if protected against UV rays with Restol Oil.

Please explain the roofing options available?

Pitched roof buildings can have any of the roofing options that we provide, whereas the single slope buildings are only available with steel roofing sheets.

Felt Tiles is standard on the pitched roof garden rooms and garages. They are created in a sheet format that has 4 tiles on each sheet – the above tile covers the lower sheet by 50% to provide a double layer of tiles. In addition to this we also cover the roof with breathable underfelt before the tiles are fitted – which creates a 3 layer roofing system with an average lifespan of 15 years.

Steel Roofing Sheets are covered with plastisol and available in a range of colours. It is fitted to the roof onto the breathable underfelt to create a 2 layer roof covering that is condensation free. When fitted to the Garden Offices the insulation in the roof ensures virtually no noise is heard during inclement weather. Average lifespan is 25 years for the steel sheeting.

Onduline Roofing is a standard roof finish for stables. It is felt and bitumen compressed into a corrugated format and can be nailed directly onto the purlins with or without boarding underneath. For the optimum life expectance of 15 years we would recommend boarding and underfelt as a base for the Onduline to sit onto. The Onduline can sit directly onto the purlins however this will reduce the average lifespan of the product. (Only available on equestrian buildings).

Tapco Slate is a perfect solution for customers looking for a tiled roof look, but would like the building supplied & fitted by one company. Fitted onto boarding, underfelt & battens the Tapco slate is a man made lightweight roofing solution that appears as realistic as natural slates. Available in a range of colours, with a maximum roof pitch of 25 degrees, the average lifespan is 40 years for this roof finish.

Green mineral felt is a polyester based felt and is much thicker and stronger than normal shed roofing felt that you would buy from a DIY store. Average lifespan is 6-8 years.

Clay or Slate Tiles @ 30 degrees. Customers that require this finish will require a tiler to supply & fit the battens, membrane, tiles and soffits for this option. Warwick Buildings will obtain the trusses and install them at 600mm centres in readiness for the tiler to continue from that point. The two end trusses will be clad, however please note that there will not be any overhangs to the gable end on this option.

How much clearance do I need around my building?

We require a minimum of 600mm around the building to be able to fit the cover strips and guttering on the outside of the building.

If you have less space available please contact us on 01926 815757, as we will discuss the options available on an individual basis – it may be that we can still accommodate your project.